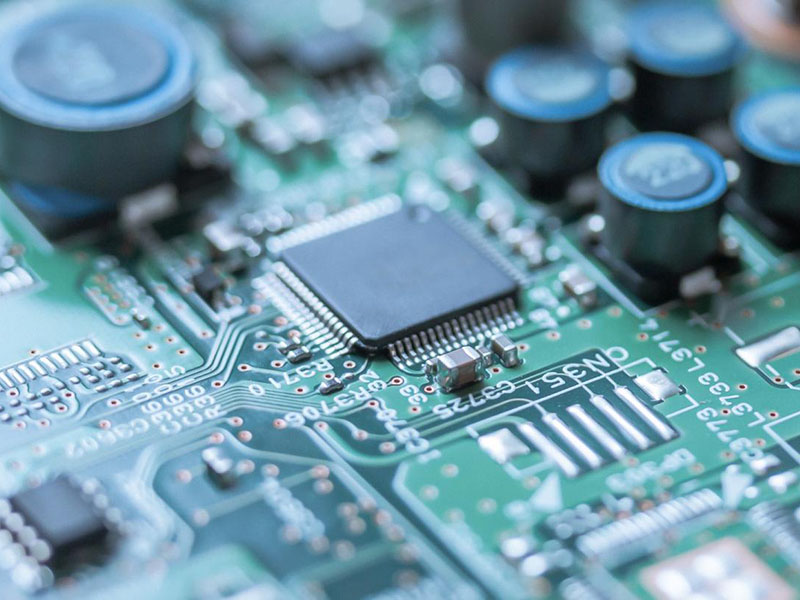

PCBs, or printed circuit boards, are a vital component of many electronic devices. They provide a platform for mounting components and connecting them with conductive traces. The thickness of the copper layer in a PCB can have a significant impact on its performance and cost. In this post, we will compare 1oz and 2oz copper PCBs to help you understand the main differences between these two options.

What is a PCB?

A PCB is a thin board made of a non-conductive material, such as fiberglass or plastic, with a layer of copper traces etched onto one or both sides. The copper traces are used to connect the various components of an electronic circuit, such as microprocessors, resistors, and capacitors. PCBs come in various sizes and shapes to fit the needs of different devices.

What is copper thickness in PCBs?

The thickness of the copper layer in a PCB is typically measured in ounces, with 1oz being equal to 1/8 inch. The thickness of the copper layer can affect the performance and cost of the PCB in several ways. For example, a thicker copper layer can improve the PCB’s current carrying capacity and heat dissipation, but it may also make the PCB more expensive to manufacture.

1oz copper PCBs

1oz copper PCBs refer to PCBs with a copper layer that is 1/8 inch thick, or 1 ounce. One of the main benefits of 1oz copper PCBs is that they are generally less expensive to manufacture than PCBs with thicker copper layers. This is because it takes less copper to make a 1oz copper PCB, and the manufacturing process is typically simpler.

However, there are some drawbacks to using 1oz copper PCBs. One of the main limitations is that they have a lower current carrying capacity compared to PCBs with thicker copper layers. This means that they may not be suitable for applications that require a high level of current to be transmitted through the PCB.

2oz copper PCBs

2oz copper PCBs refer to PCBs with a copper layer that is 1/4 inch thick, or 2 ounces. One of the main benefits of 2oz copper PCBs is that they have a higher current carrying capacity compared to 1oz copper PCBs. This makes them suitable for applications that require a high level of current to be transmitted through the PCB.

In addition, 2oz copper PCBs have improved heat dissipation compared to 1oz copper PCBs. This is because the thicker copper layer provides a larger surface area for heat to be conducted away from the components.

However, there are some drawbacks to using 2oz copper PCBs. One of the main limitations is that they are generally more expensive to manufacture than 1oz copper PCBs. This is because it takes more copper to make a 2oz copper PCB, and the manufacturing process is typically more complex.

Comparison of 1oz and 2oz copper PCBs

When deciding which type of copper PCB to use in your project, it’s important to consider the trade-offs between cost, performance, and manufacturing complexity. Here is a summary of the main differences between 1oz and 2oz copper PCBs:

- Cost: 1oz copper PCBs are generally less expensive to manufacture than 2oz copper PCBs.

- Current carrying capacity: 2oz copper PCBs have a higher current carrying capacity than 1oz copper PCBs.

- Heat dissipation: 2oz copper PCBs have improved heat dissipation compared to 1oz copper PCBs.

- Manufacturing complexity: 2oz copper PCBs are typically more complex to manufacture than 1oz copper PCBs.

In general, 1oz copper PCBs may be a good choice for projects that require a low to moderate level of current and do not have strict requirements for heat dissipation. They may also be a good choice for projects with tight budgets, as they are less expensive to manufacture.

On the other hand, 2oz copper PCBs may be a good choice for projects that require a high level of current or have strict requirements for heat dissipation. They may also be a good choice for projects that can afford the higher cost of manufacturing.

It’s worth noting that 1oz and 2oz copper PCBs are not the only options available. PCBs with even thicker copper layers, such as 3oz or 4oz, are also available. However, these options may be even more expensive to manufacture and may not be necessary for most projects.

Conclusion

In summary, 1oz and 2oz copper PCBs are two options for the thickness of the copper layer in a PCB. 1oz copper PCBs are generally less expensive to manufacture, but have a lower current carrying capacity and less effective heat dissipation compared to 2oz copper PCBs. 2oz copper PCBs have a higher current carrying capacity and improved heat dissipation, but are generally more expensive to manufacture. When deciding which type of copper PCB to use in your project, consider the trade-offs between cost, performance, and manufacturing complexity.